This page is under construction! Please check back later - we have cool things coming!

Black Dye

Black dye is your best option for aesthetic parts on a budget. Black dye will even out the color gradient on surfaces, make your logos pop, and bring your parts to the next level. Depending on part geometry, dyeing only adds about 5% to the cost of your part and does not increase lead time. We are able to dye in large batches with no labor due to our automatic Girbau dye system.

Black dye is a basic finish. For more advanced finishes, see our other finishes in the “Finishing and Services” tab above.

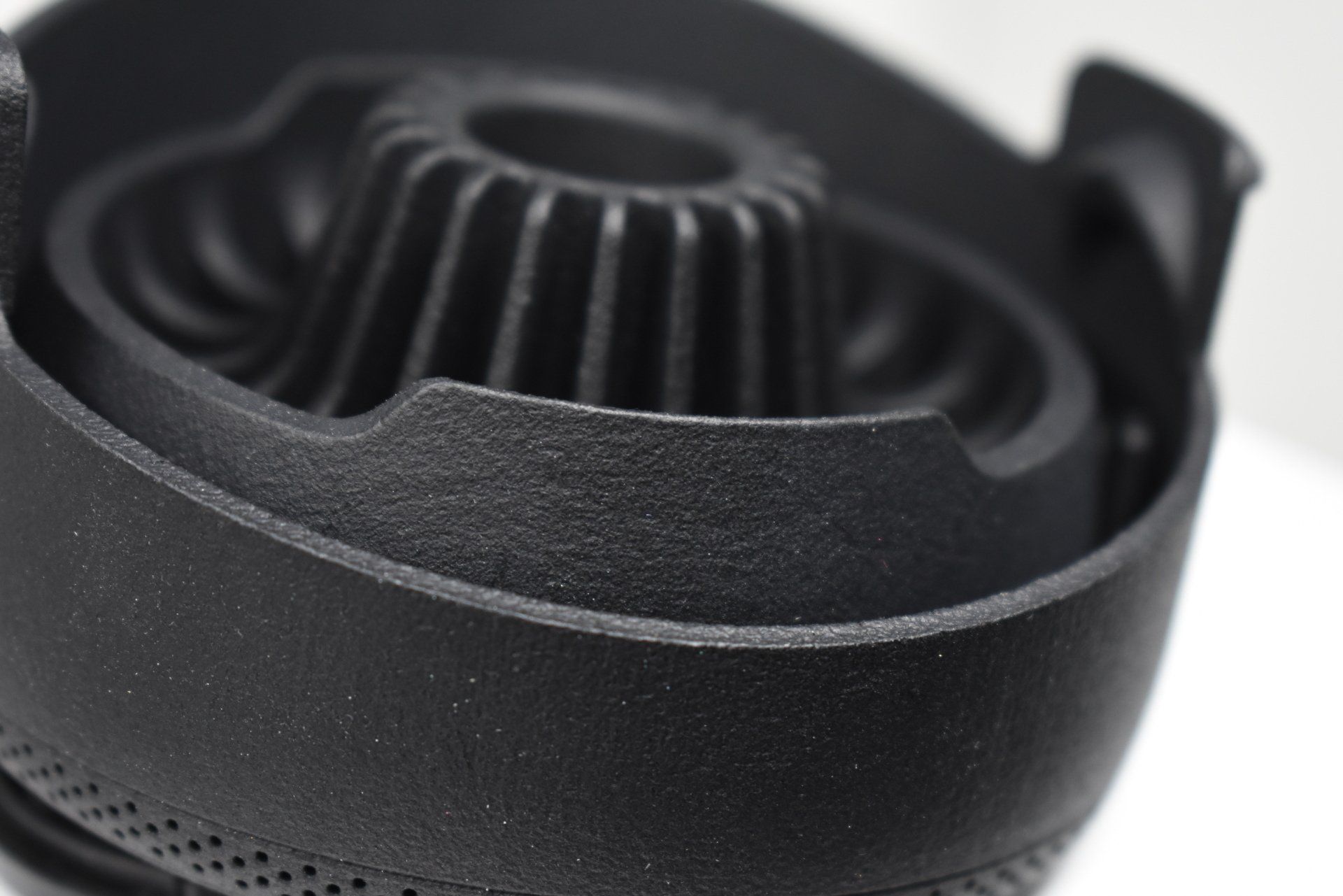

Appearance

The standard raw grey MJF finish can be lighter in some areas and darker in others, making it difficult to see engravings, logos, and fine features.

The color variation on gray parts is caused by variable section thickness, variation in the bead blasting process, and the temperature of the part while printing. In our experience, most grey parts have pretty consistent coloring, but perfect color is not a guarantee.

Automatic Dyeing by Girbau

When parts are dyed black, the color is the same everywhere and all of your design features will stand out more clearly.

To keep labor costs low and batch-to-batch color consistency identical, we use a Girbau automatic dyeing system. This system uses a special process to ensure dye concentration levels, dye temperature, and agitation of the dye are all performed repeatably. This ensures that an order made in April is the same uniform shade of black as your January order.

Parts We Sell

Fluid Systems

Packaging Machinery

Factory Hardware

Custom Brackets

Custom Pole Brackets

Jigs and Fixtures

Video Game Controllers

Consumer Electronics