Design For Additive Manufacturing (DFAM)

Lower Cost, Increase Performance

Remarkable products start with remarkable designs, especially when the design is made with the production process in mind. Work with our design team to achieve better surface finishes, tighter tolerances, lower production costs, and more attractive parts. There are many digital tools that we use to help you achieve your goals.

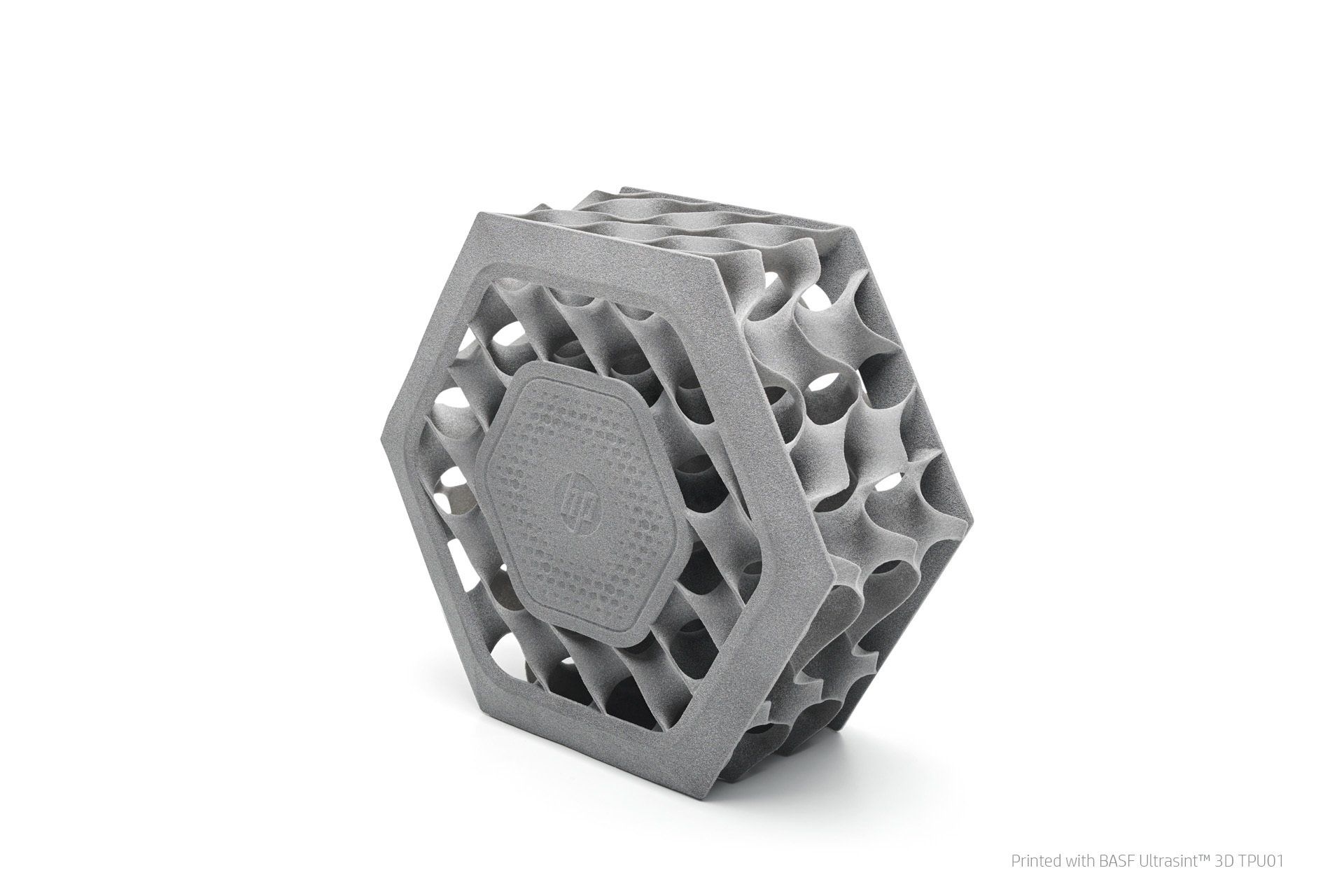

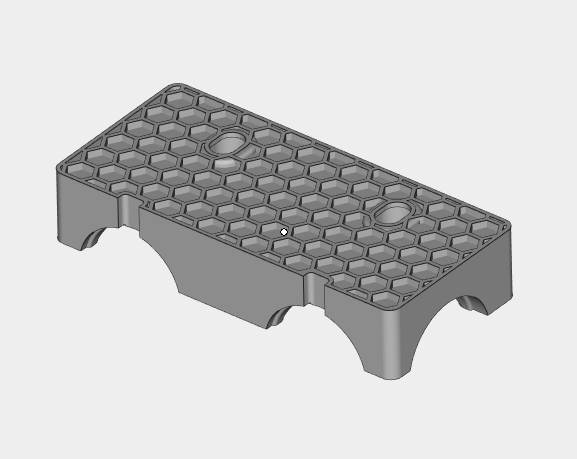

Lower Production Costs

- Save up to 50% on part production costs by decreasing part mass, adding lattice structures, increasing wall thickness, adding ribs, and improving 3D nesting performance

- The main design factors that influence part cost are part mass, part bounding box size, part shape, difficult feature resolution, and 3D "nestability" (this is how well parts fit together in the build volume)

- If you are looking to further decrease costs with large manufacturing orders over 100 pieces, please contact us for bulk pricing and manufacturing contracts.

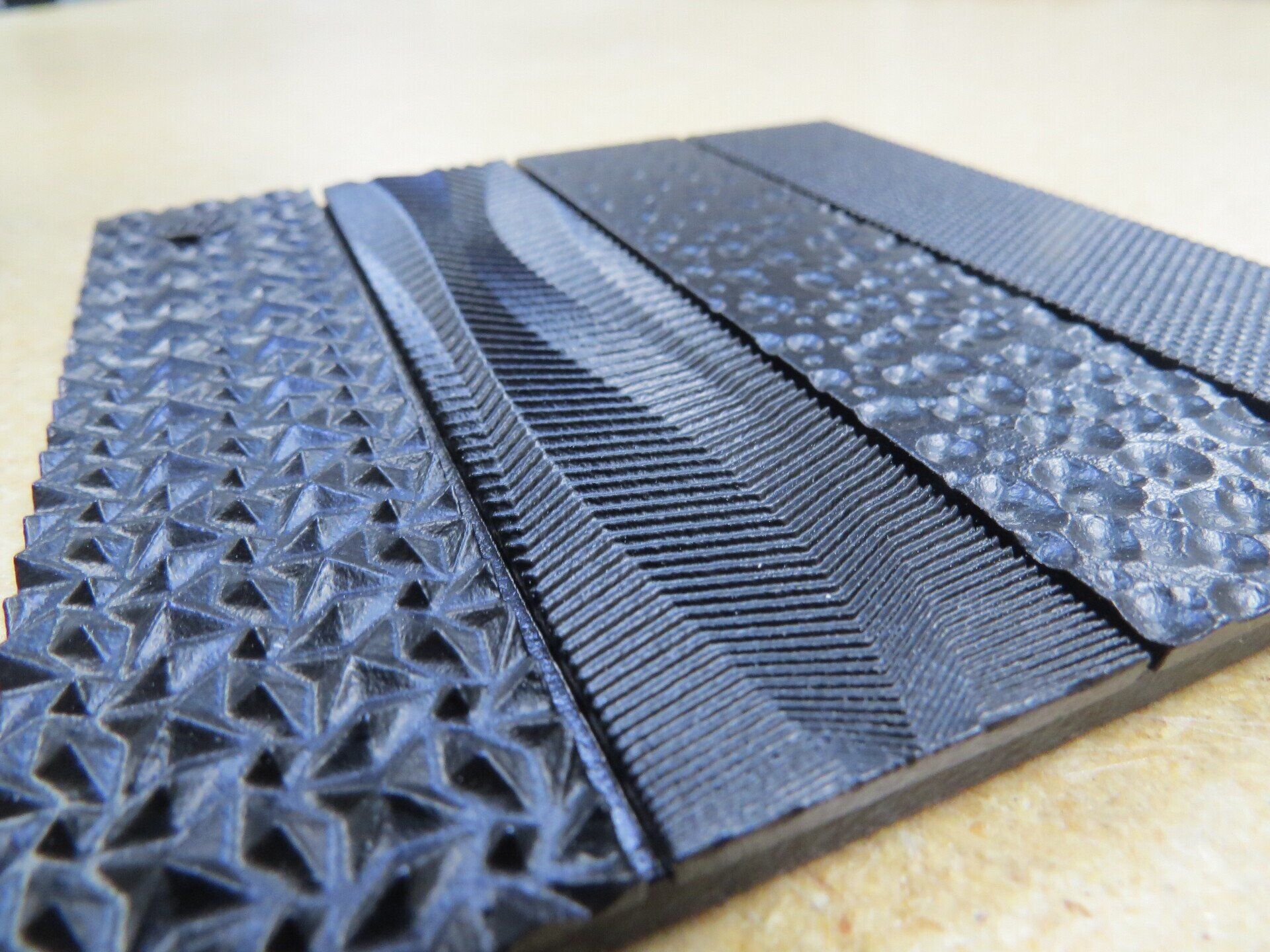

Surface Texturing

- Add surface textures such as leather grain, wood grain, organic lattices, logo patterns, and more.

- With traditional manufacturing, surface textures are incredibly expensive and difficult to produce.

- 3D Printing offers the ability to make your designs beautiful at almost no cost. The only cost is the time it takes to add textures to your surfaces.