Get in touch

555-555-5555

mymail@mailservice.com

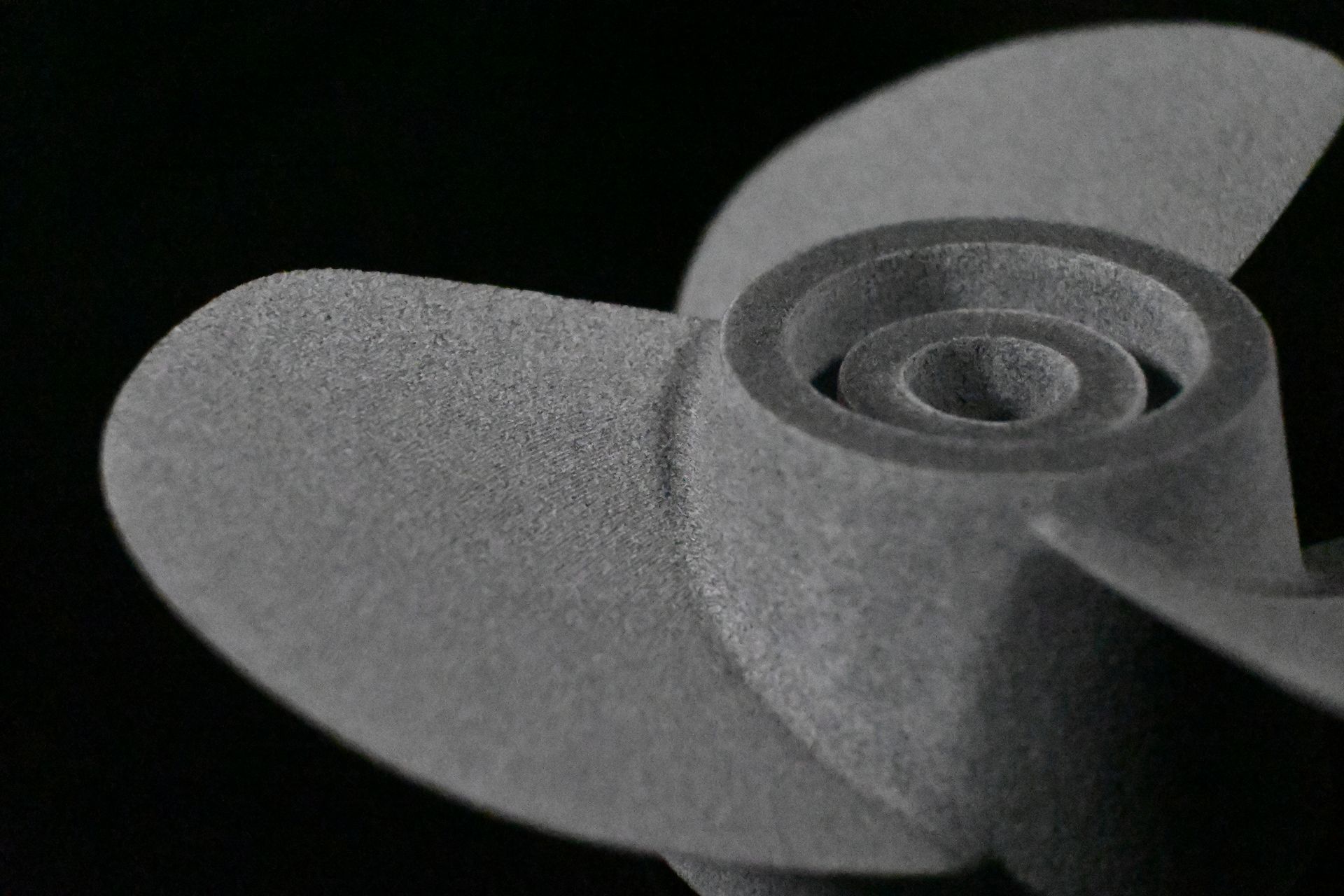

Raw Grey Finish- Multi jet fusion 3D Printed Parts

- By Cody Laursen

- •

- 29 Jun, 2023

- •

Figuring out the best finish, FOR YOU!

The RAW GREY finish for multi-jet Fusion 3D printed parts, is how the parts come out of the printer with no post processing. When the parts come out of the printer they are covered in a loose white powder similar to baking powder. Most of the powder is wiped off in the processing station; to make the parts completely clean we blast the model surfaces with the very fine spherical glass bead which knocks off all the infused powder. What we are left with is a raw gray finish.

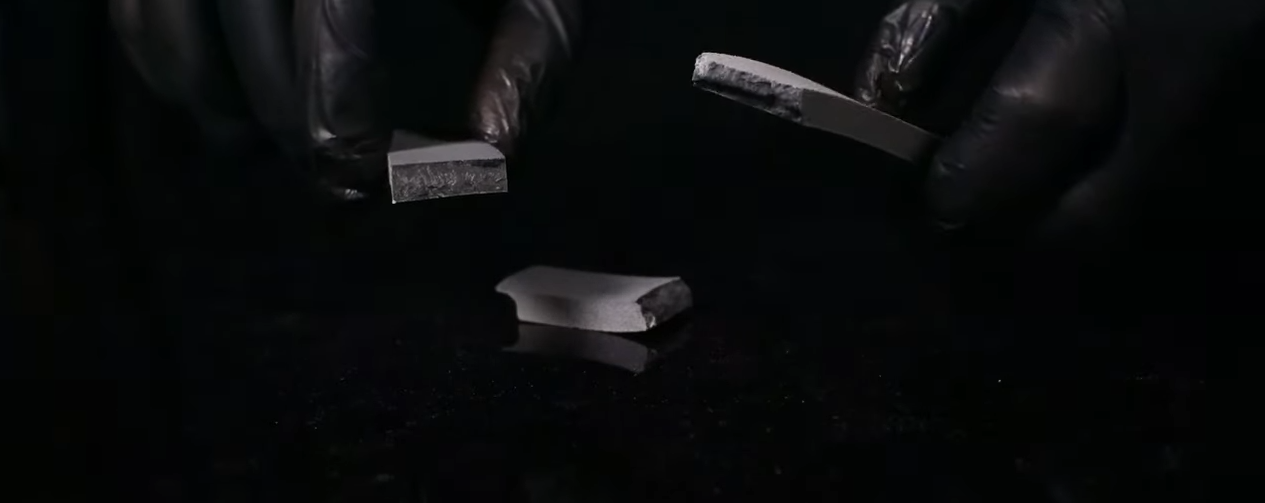

A lot of people do not realize that MJF parts are actually black inside, there's about a 200 to 300 Micron layer crust of grey on the surface because the parts print in a white powder and then the fusing agent that melts the plastic together is black but that transition zone is actually grey. If you were to cut the model with a knife or snap it in half you would see that the inside of the model is actually a kind of a graphite black color.

A lot of people do not realize that MJF parts are actually black inside, there's about a 200 to 300 Micron layer crust of grey on the surface because the parts print in a white powder and then the fusing agent that melts the plastic together is black but that transition zone is actually grey. If you were to cut the model with a knife or snap it in half you would see that the inside of the model is actually a kind of a graphite black color.

There are a few benefits to the raw finish, the main benefit is that it's just cheap all of our other finishes have some sort of extra cost whereas the raw gray finish adds no cost the parts generally still look pretty darn good with the raw gray finish but it looks kind of unique it doesn't look like a normal part you would buy at a store; and the surfaces also will have that unique powder based sugar cube finish that SLS and MJF parts have

The main downsides to the raw finish would be that the finish just kind of looks different sometimes the finish will have lighter spots and darker spots from blasting. The blasting will reveal some of that dark inner core of the part. Sometimes the printing chamber will be hotter or colder and that could change the amount of powder stuck to the surface and change the color; so there's just some variation batch to batch.

The main applications that we see for the raw finish are prototypes and parts that just don't matter aesthetically. A lot of times people order prototypes and are just checking if they fit and how they will mate up to other parts. For end-use applications where you have a part inside of a say an electrical enclosure inside of an engine compartment or maybe anywhere that's hidden and not going to be shown in the public.

Parts We Sell

Fluid Systems

Packaging Machinery

Factory Hardware

Custom Brackets

Custom Pole Brackets

Jigs and Fixtures

Video Game Controllers

Consumer Electronics